Intro

Efficient production begins with a clear concept

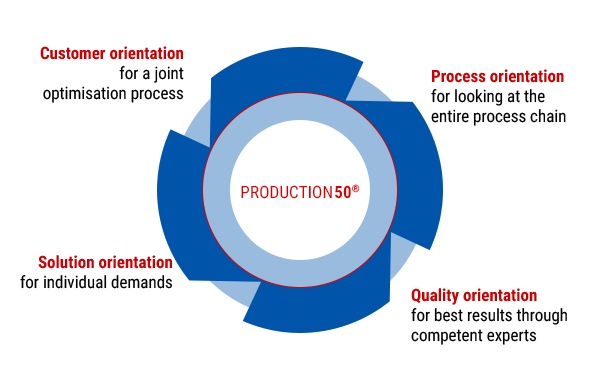

To optimise processes, the Production50® methodology focuses on a strong partnership and a professional exchange between yourself and our client advisors as process optimisers. Essentially, it is about creating a new perspective: away from the actual tool itself towards the complete production process of die and mold. This change of perspective clears the way for new solutions.

Production50®

Moulds Kaizen into our company

The Kaizen philosophy has successfully established itself as a continuous improvement process in many companies. Production50® was developed according to the Kaizen tradition to take our philosophy one step further. The pledge is to make the path from the workpiece to the finished tool as efficient as possible for you.

With Production50®, you have a partnership-based consulting methodology by your side that serves the sole purpose of sustainably improving process quality in terms of speed, efficiency, throughput, surface quality, dimensional accuracy, precision and safety.

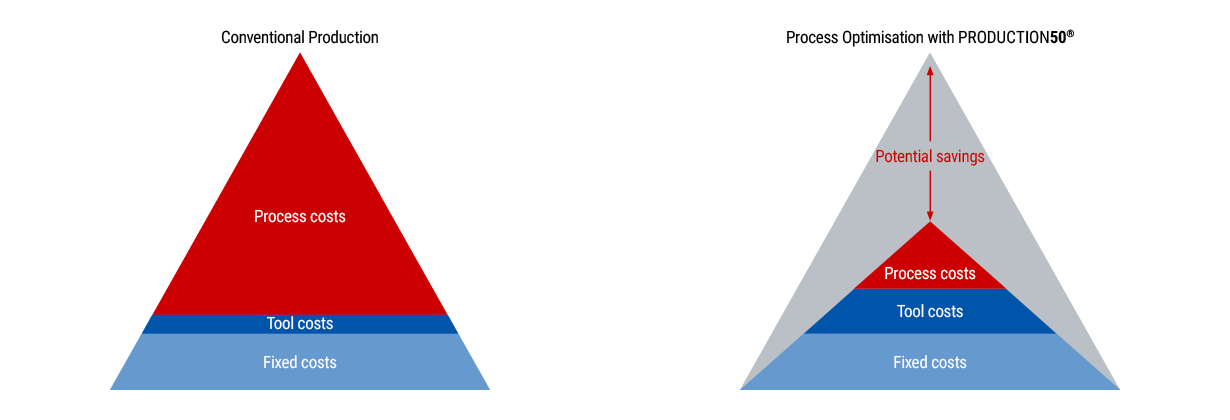

Regardless of whether it's stamping or injection moulding technology – ultimately production costs can be reduced by up to 50% if we jointly develop strategies for efficient production by applying the Production50® methodology.

CUSTOMER FOCUS

For a joint optimisation process

You set the targets. We jointly develop needs-based optimisation approaches. Qualified and experienced technicians in your region are at your disposal to assist you. We are neither a management consultancy nor an ordinary tool supplier. Our concept is based on the notion of a long-term partnership on an equal footing.

PROCESS ORIENTATION

For the consideration of the entire process chain

Based on concrete goals and specific customer requirements our process optimizers analyze the entire production process together with our customers. All relevant production steps are included in the analysis. From the determination of the actual condition to the practical implementation and profitability calculation up to the sustainable implementation into the production the result leads to a secure and efficient overall process.

FOCUS ON QUALITY AND SOLUTIONS

For individual challenges and the best results

Our employees are process optimisers: in this role they combine many years of experience and application expertise which they bring to your company using Production50® They work with you to develop production strategies tailored to your individual objectives. In doing so, they take into account the technical as well as the economic challenges in order to sustainably optimise the production processes.

SAVING POTENTIALS

It’s not the individual tool that is decisive

Your tools and moulds have a price and a better margin with Production50®.

Our process optimisers draw on the experience and data of countless successful optimisations. We share this knowledge with you as part of our individual consulting services. Ultimately, production costs can be reduced by up to 50% if we jointly develop strategies for efficient production by applying the Production50® methodology.